Blow Molding vs. Injection Molding: What’s the Difference?

When it comes to manufacturing plastic products, two of the most common methods are blow molding and injection molding. While both processes involve shaping plastic, they are used for different types of products and have distinct advantages. Understanding the differences between blow molding and injection molding can help businesses make the right choice for their production needs. At Nirdosh Polymers, we specialize in both techniques and offer expert guidance on which method is best suited for your project.

What Is Blow Molding?

Blow molding is a manufacturing process used to create hollow plastic parts, such as bottles, containers, and other similar products. In this process, melted plastic is extruded into a tube-like shape called a “parison.” This parison is then clamped into a mold, and air is blown into it, inflating the plastic to fit the mold’s shape. Once cooled, the plastic retains the hollow shape, resulting in the final product.

Key Benefits of Blow Molding:

- Cost Efficiency for Hollow Products: Blow molding is ideal for producing hollow parts in large quantities, such as plastic bottles and fuel tanks.

- Lightweight Products: Since the process focuses on creating hollow objects, blow-molded products are typically lightweight.

- High Production Volume: Blow molding is highly efficient, enabling the production of a large number of products in a short amount of time.

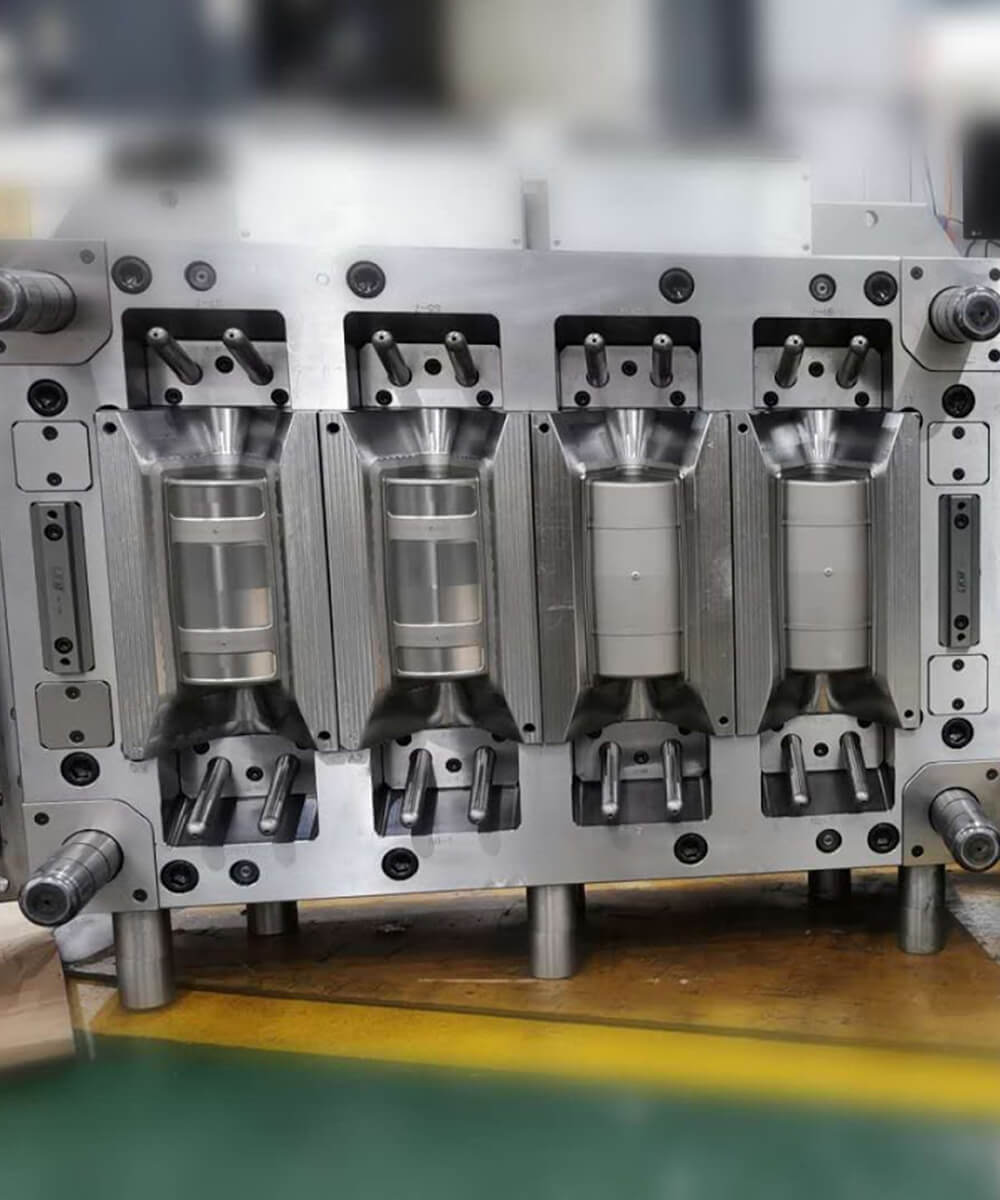

What Is Injection Molding?

Injection molding, on the other hand, is used for producing solid plastic parts. In this process, molten plastic is injected into a mold cavity at high pressure. The plastic cools and hardens into the desired shape before being ejected from the mold. Injection molding is highly versatile and is used for creating a wide variety of plastic components, ranging from small precision parts to larger structural items.

Key Benefits of Injection Molding:

- Precision and Consistency: Injection molding is highly accurate and capable of producing complex parts with tight tolerances.

- Material Variety: A wide range of materials can be used, allowing for the creation of parts with different properties, such as heat resistance or flexibility.

- Minimal Waste: The injection molding process generates little waste, as excess material can often be reused.

Comparing Blow Molding and Injection Molding

- Product Shape and Functionality

- Blow Molding: Best for creating hollow products like bottles, tanks, and containers.

- Injection Molding: Ideal for producing solid, complex parts like automotive components, electronic housings, and household items.

- Production Cost

- Blow Molding: Generally more cost-effective for producing large quantities of hollow items.

- Injection Molding: Although the initial tooling cost may be higher, the per-unit cost decreases significantly with larger production runs, making it ideal for high-volume projects.

- Design Flexibility

- Blow Molding: Limited to simpler, hollow designs.

- Injection Molding: Offers greater design flexibility, allowing for intricate shapes and features, such as threads or logos.

- Material Use

- Blow Molding: Primarily uses thermoplastics that can be easily melted and inflated into hollow forms.

- Injection Molding: Accommodates a broader range of materials, including both thermoplastics and thermosetting plastics.

Which Process Is Right for Your Project?

The choice between blow molding and injection molding depends largely on the type of product you want to create. If your project involves hollow components like bottles or containers, blow molding is the clear choice. For solid parts requiring high precision, such as medical devices or automotive components, injection molding is the superior option.

At Nirdosh Polymers, we offer both blow molding and injection molding services to meet your manufacturing needs. Our expert team can help you determine which process is best suited for your project based on the design, material requirements, and production volume. Contact us at Nirdosh Polymers today to learn more about our capabilities and get started on your next project!