At Nirdosh Polymers, we stand as a beacon of excellence with 42 years of expertise in injection moulding products manufacturing. Mould design is the cornerstone of our process, ensuring the creation of precision components that meet the highest industry standards.

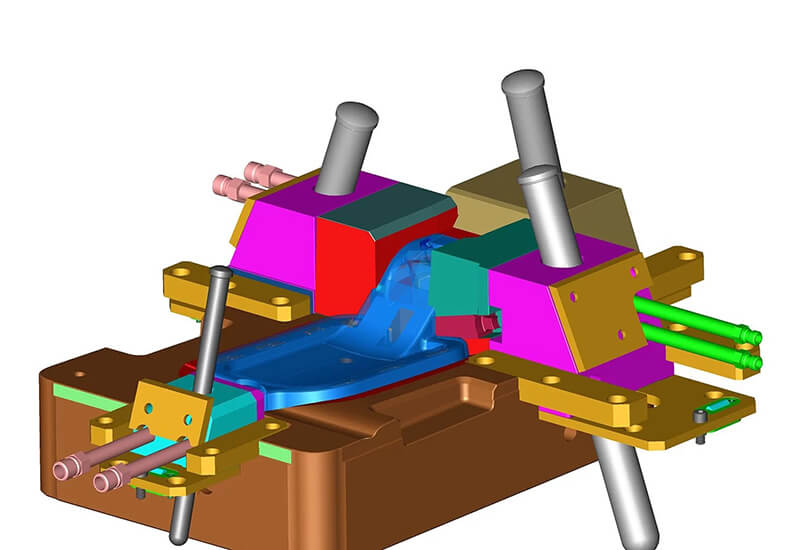

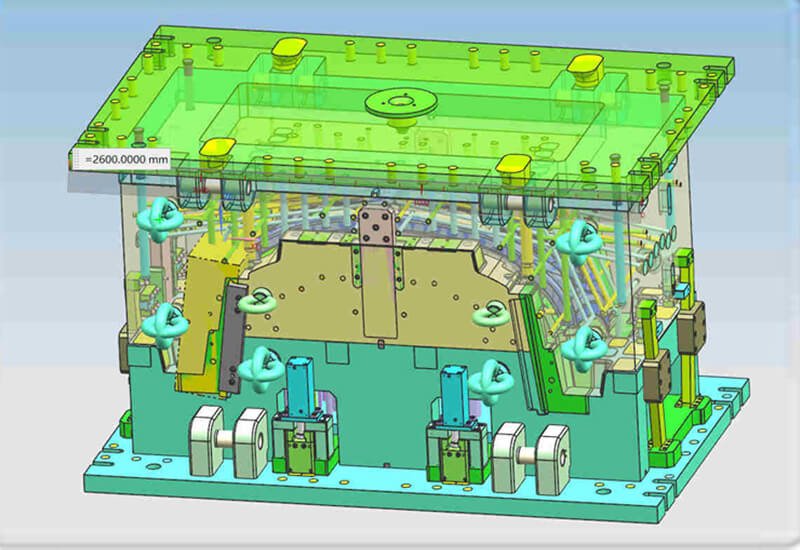

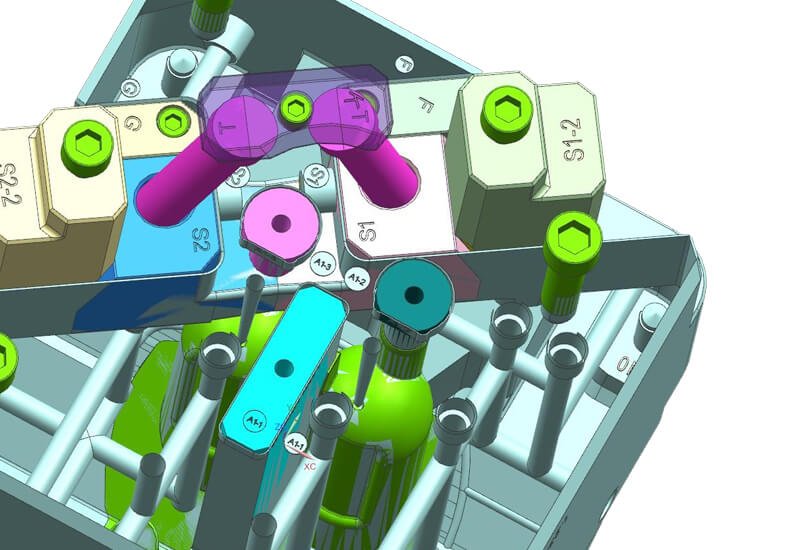

Our seasoned team, well-versed in crafting intricate and precise moulds, utilizes the latest technology and software. Through meticulous 3D modeling, we guarantee a perfect fit, efficient production, and superior quality in every injection moulded component. With a client base of over 500 satisfied partners, we continue to redefine industry standards, offering innovation, reliability, and excellence in every project.

Advantages of a Well-designed Mould

Increased

Production Efficiency

Improved

Product Quality

Cost Savings Through Reduced Waste and Rework

Faster

Time to Market

Our Mould Design Process

Consultation

We work closely with you to understand your needs and requirements, and to determine the best design solution for your product.

Conceptual Design

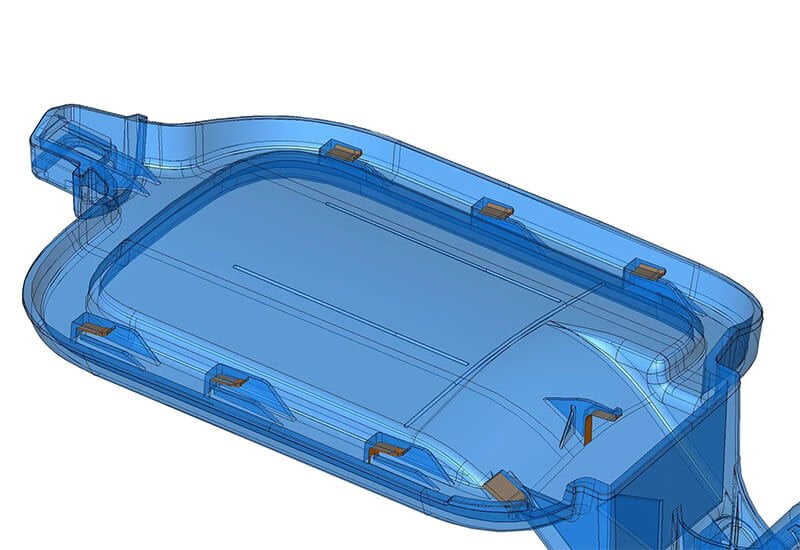

Our team creates a 3D model of your product, considering factors such as material, manufacturing process, and target market.

Detailed Design

We refine the 3D model and incorporate precise dimensions, as well as any necessary reinforcements, cooling systems, and ejection mechanisms.

Prototyping

We create a physical prototype of your product to test the mould design and ensure that it meets your requirements.

Testing and Validation

We subject the prototype to various tests, including thermal and mechanical stress, to validate the design and make any necessary adjustments.

Final Mould Design

We finalize the mould design, incorporating any necessary changes, and send it to the manufacturing process.

Choose Us for Your Mould Design Needs

Our team of experts has the experience and expertise to create precise, high-quality moulds that meet your specific needs and requirements. Contact us today to learn more about our mould design services.