Ways To Select A Plastics Manufacturer For Your Project

Choosing the right plastics manufacturer is crucial for the success of any project involving plastic parts. The decision can affect the quality of your products, the efficiency of your production, and ultimately, the satisfaction of your customers. At Nirdosh Polymers, we understand the importance of this decision. Here are some key factors to consider when selecting a plastics manufacturer for your project.

1. Expertise and Experience

Look for a manufacturer with extensive experience in the plastics industry. An experienced provider will have a deep understanding of different materials, production processes, and the challenges associated with plastic manufacturing. Check their track record in handling projects similar to yours. Nirdosh Polymers, for example, has years of expertise in diverse sectors, ensuring that we can handle complex and specialized requirements with ease.

2. Quality Assurance

Quality is non-negotiable. Inquire about the manufacturer’s quality assurance processes. Do they adhere to international standards such as ISO 9001? Review their quality control measures during the production process. A reputable manufacturer should have stringent quality checks in place to ensure that each product meets the required specifications and is free from defects.

3. Capability and Technology

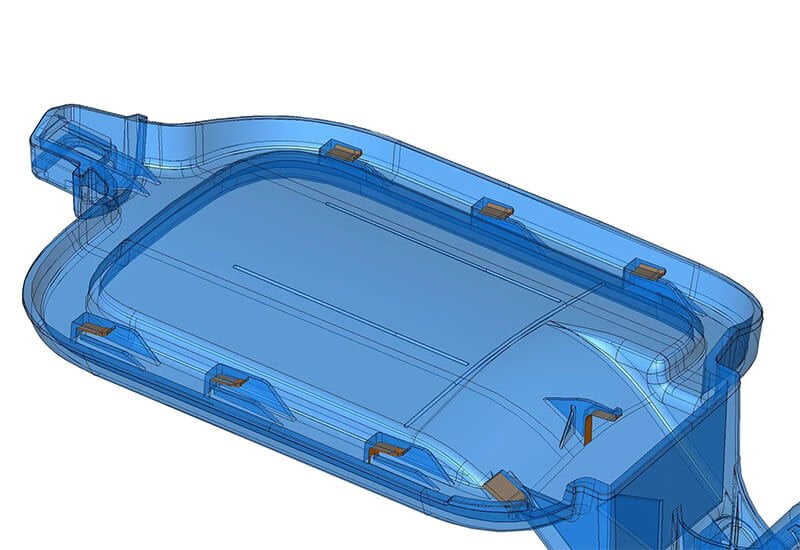

Assess whether the manufacturer has the capability and the latest technology to meet your project’s specific needs. This includes having the right machinery, the latest injection molding techniques, and the ability to produce high precision parts. A manufacturer that invests in cutting-edge technology is likely to deliver higher efficiency, better quality, and innovative solutions.

4. Material Selection

The right material selection is critical for the success of your plastic parts. Your manufacturer should have expertise in a wide range of materials and be able to advise you on the best choices based on the performance requirements and environmental conditions of your project. They should also be proactive in suggesting cost-effective alternatives that do not compromise quality.

5. Production Capacity and Flexibility

Evaluate the manufacturer’s production capacity to ensure they can meet your volume requirements within your timeline. Additionally, check their flexibility in handling both high-volume production and smaller, more custom orders. This flexibility can be crucial for managing varying demand cycles and for projects that require a phased rollout.

6. Environmental Considerations

With increasing concerns about environmental sustainability, it’s important to choose a manufacturer who prioritizes eco-friendly practices. Check if they use recyclable materials, have waste reduction measures, and follow environmentally responsible manufacturing processes. Partnering with a manufacturer who is committed to sustainability can also enhance your brand’s reputation.

7. Customer Service and Communication

Effective communication is essential for any successful partnership. The manufacturer should be responsive, transparent, and easy to work with. They should provide clear and consistent communication throughout the production process and be readily available to address any queries or issues that arise.

8. Competitive Pricing

While cost should not be the only factor, it is undoubtedly important. Obtain quotes from several manufacturers to compare pricing. However, consider what is included in those prices, such as additional services like design assistance, material testing, or post-production support. Opt for a manufacturer who offers a fair price while still meeting all other criteria.

Conclusion

Selecting the right plastics manufacturer is a pivotal decision. By considering these factors, you can choose a partner that not only meets your production needs but also contributes to the overall success of your project. At Nirdosh Polymers, we pride ourselves on meeting these standards, providing top-quality products and services that our clients can rely on. Visit our website to learn more about how we can bring your project to life with expertise and precision.