Mastering the Art of Plastic Injection Molding: Exploring Design, Development, and Manufacturing

Plastic injection molding is a versatile and efficient manufacturing process that has transformed numerous industries. From intricate components to consumer products, the possibilities are vast. In this blog post, we delve into the world of plastic injection molding, focusing on the critical aspects of mold design, development, and the overall manufacturing process.

Join us as we uncover the key elements and considerations necessary to master the art of plastic injection molding.

- The Fundamentals of Plastic Injection Molding

- Understanding the core principles and steps involved in the plastic injection molding process, from material selection to finished product.

- Exploring the advantages and limitations of plastic injection molding compared to other manufacturing methods.

- Highlighting real-life examples of products made through plastic injection molding.

- Design for Injection Molding: Optimizing Product and Mold Design

- Discussing the essential design guidelines for plastic injection molding, including wall thickness, draft angles, and undercuts.

- Exploring techniques for part consolidation, ensuring efficient production and cost savings.

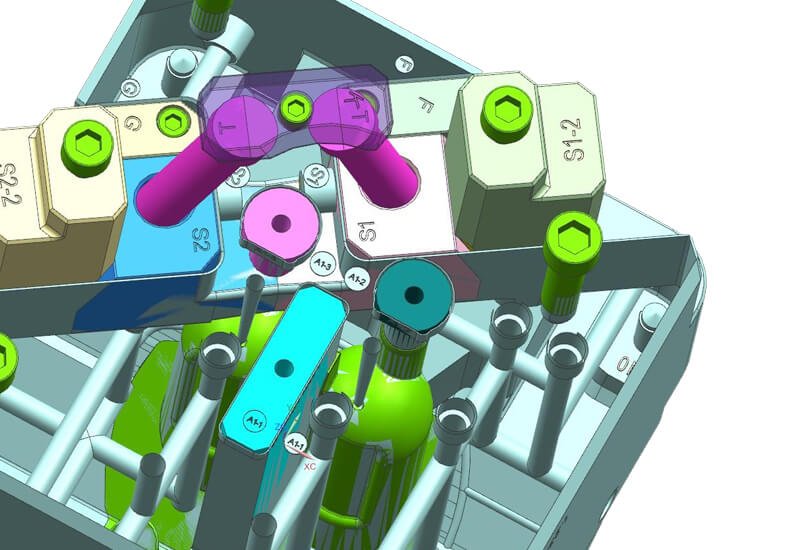

- Examining considerations for designing molds, such as gate placement, ejection methods, and cooling systems.

- Mold Development: From Concept to Production

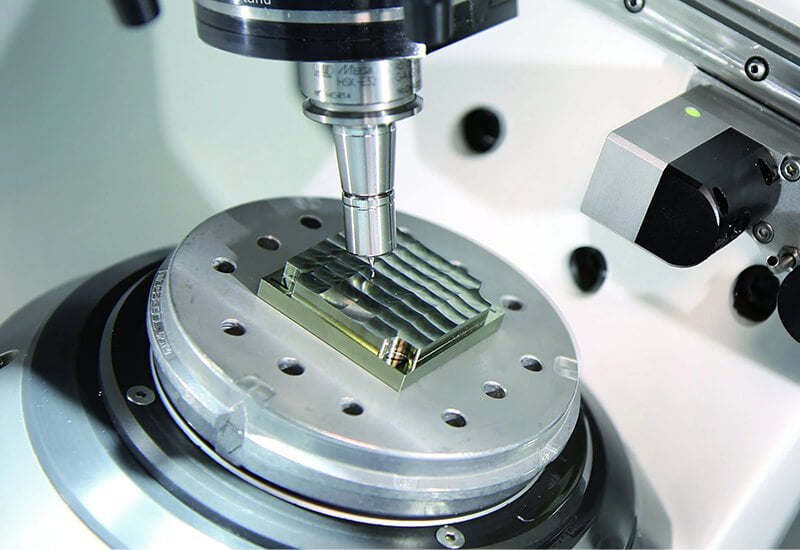

- Exploring the key stages involved in mold development, from initial concept and design to prototyping and final production.

- Discussing the importance of collaboration between designers, engineers, and mold manufacturers in ensuring optimal mold functionality.

- Highlighting emerging technologies and trends in mold development, such as 3D printing and simulation software.

- Material Selection for Injection Molding

- Providing insights into different types of plastic materials used in injection molding and their characteristics.

- Discussing the factors to consider when selecting the appropriate material for specific applications, including strength, durability, and chemical resistance.

- Examining the impact of material properties on mold design, processing parameters, and final product quality.

- Optimizing the Injection Molding Process

- Exploring the variables and parameters that affect the injection molding process, such as temperature, pressure, and cycle time.

- Discussing techniques for troubleshooting common issues in injection molding, such as shrinkage, warpage, and sink marks.

- Highlighting strategies for process optimization, including lean manufacturing principles and automation technologies.

- Ensuring Quality and Efficiency in Plastic Injection Molding

- Discussing quality control measures in injection molding, such as inspection techniques, process monitoring, and statistical analysis.

- Exploring sustainable practices in plastic injection molding, including waste reduction and recycling initiatives.

- Examining the importance of continuous improvement and innovation in the field of plastic injection molding.

Plastic injection molding offers a multitude of possibilities for manufacturing high-quality plastic products. By mastering the art of mold design, development, and the injection molding process, businesses can unlock new opportunities and drive innovation. Through a combination of technical expertise, design optimization, and efficient production practices, the potential for success in plastic injection molding is limitless.